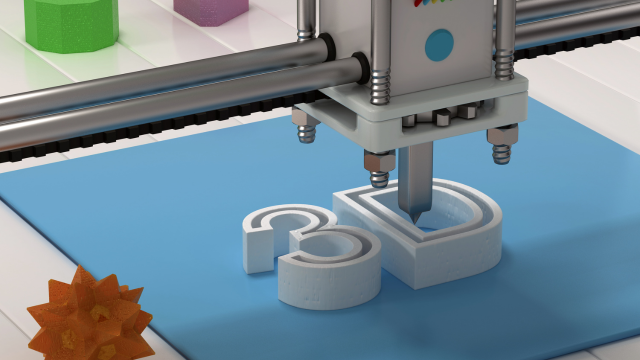

In recent years, the automotive sector has witnessed a revolutionary transformation with the integration of 3D printing technology. This innovative approach has brought about significant changes, revolutionizing the way vehicles are designed, manufactured, and even customized. The fusion of 3D printing and the automotive industry is reshaping the traditional manufacturing landscape, offering numerous benefits and opportunities for growth. In this article, we’ll delve into the various aspects of how 3D printing is influencing the automotive sector.

1. Introduction to 3D Printing in Automotive

The automotive industry has always been at the forefront of technological advancements, and 3D printing is no exception. This section provides an overview of how 3D printing works and its relevance in the automotive context.

2. Advantages of 3D Printing

2.1. Design Flexibility and Customization

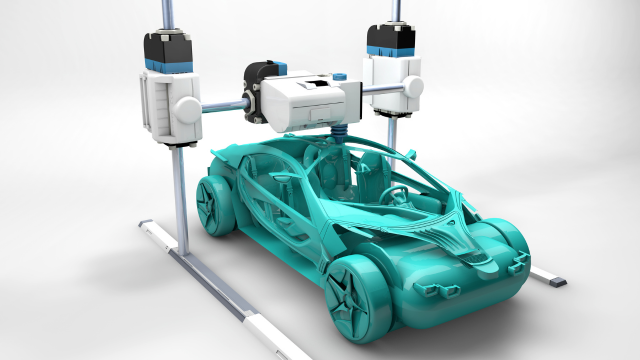

One of the most profound impacts of 3D printing on the automotive sector is its ability to enable intricate design and customization. Manufacturers can now create complex geometries and intricate parts that were previously challenging or impossible to produce using traditional manufacturing methods.

2.2. Rapid Prototyping and Iteration

3D printing has dramatically accelerated the prototyping phase of vehicle development. Manufacturers can quickly create prototypes of various components, test them, and make necessary iterations, significantly reducing the time and cost required for traditional prototyping.

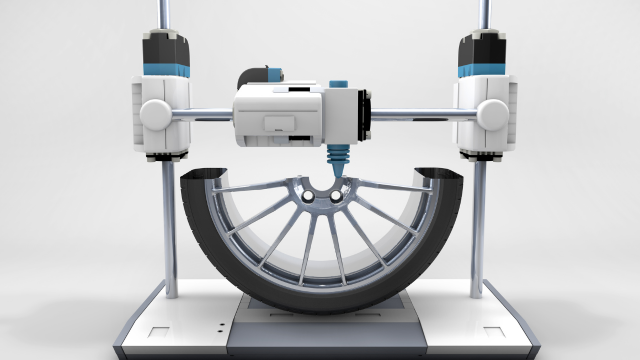

2.3. Lightweight Structures and Enhanced Performance

By utilizing advanced materials like carbon fiber-reinforced polymers, 3D printing allows the creation of lightweight yet robust parts. This not only improves fuel efficiency but also enhances overall vehicle performance and safety.

3. Transforming Production Processes

3.1. Reduced Lead Times

Traditional manufacturing involves numerous steps and intermediaries, leading to longer production times. With 3D printing, the production process becomes more streamlined, minimizing lead times and enabling faster delivery of vehicles to the market.

3.2. On-Demand Manufacturing

The concept of on-demand manufacturing becomes viable through 3D printing. Manufacturers can produce spare parts as needed, reducing inventory costs and waste, while ensuring that parts are readily available when required.

4. Sustainable Manufacturing

4.1. Waste Reduction

3D printing is an additive manufacturing process, which means it only uses the material required to build the object, minimizing waste. This contrasts with subtractive manufacturing, where excess material is often discarded.

4.2. Energy Efficiency

The localized and precise nature of 3D printing reduces energy consumption compared to traditional manufacturing methods that involve extensive machining and transportation of materials.

5. Challenges and Future Prospects

5.1. Material Limitations

While 3D printing offers a wide range of materials, some critical automotive-grade materials are still under development. Achieving the desired strength, durability, and thermal resistance remains a challenge.

5.2. Scalability

As of now, 3D printing is more suitable for low-volume production. Scaling up to meet the demands of mass production while maintaining quality standards presents a significant hurdle.

6. Conclusion

The integration of 3D printing technology into the automotive sector is undoubtedly a game-changer. From revolutionizing design possibilities to accelerating production processes and fostering sustainability, the influence of 3D printing is reshaping the industry’s landscape. As technology continues to advance and challenges are addressed, we can expect even more groundbreaking developments in the future.

FAQs (Frequently Asked Questions)

How does 3D printing benefit vehicle customization?

3D printing allows manufacturers to create intricate and customized designs, giving customers the option to personalize their vehicles to a greater extent.

Can 3D-printed automotive parts match the quality of traditional components?

With advancements in materials and printing techniques, 3D-printed parts can achieve and sometimes even surpass the quality of traditional components.

What role does sustainability play in 3D printing for automotive applications?

3D printing’s reduced waste generation and energy efficiency contribute to more sustainable manufacturing practices in the automotive industry.

Are there any safety concerns associated with using 3D-printed parts in vehicles?

Manufacturers need to adhere to rigorous testing and quality control standards to ensure the safety and reliability of 3D-printed parts used in vehicles.